Vision and roadmap

Australia has everything it needs to make it a green hydrogen powerhouse. Our technology can help make it a reality.

Use cases

We believe our technology solves real challenges currently faced by multiple industries, and provides opportunity for international distribution of green hydrogen.

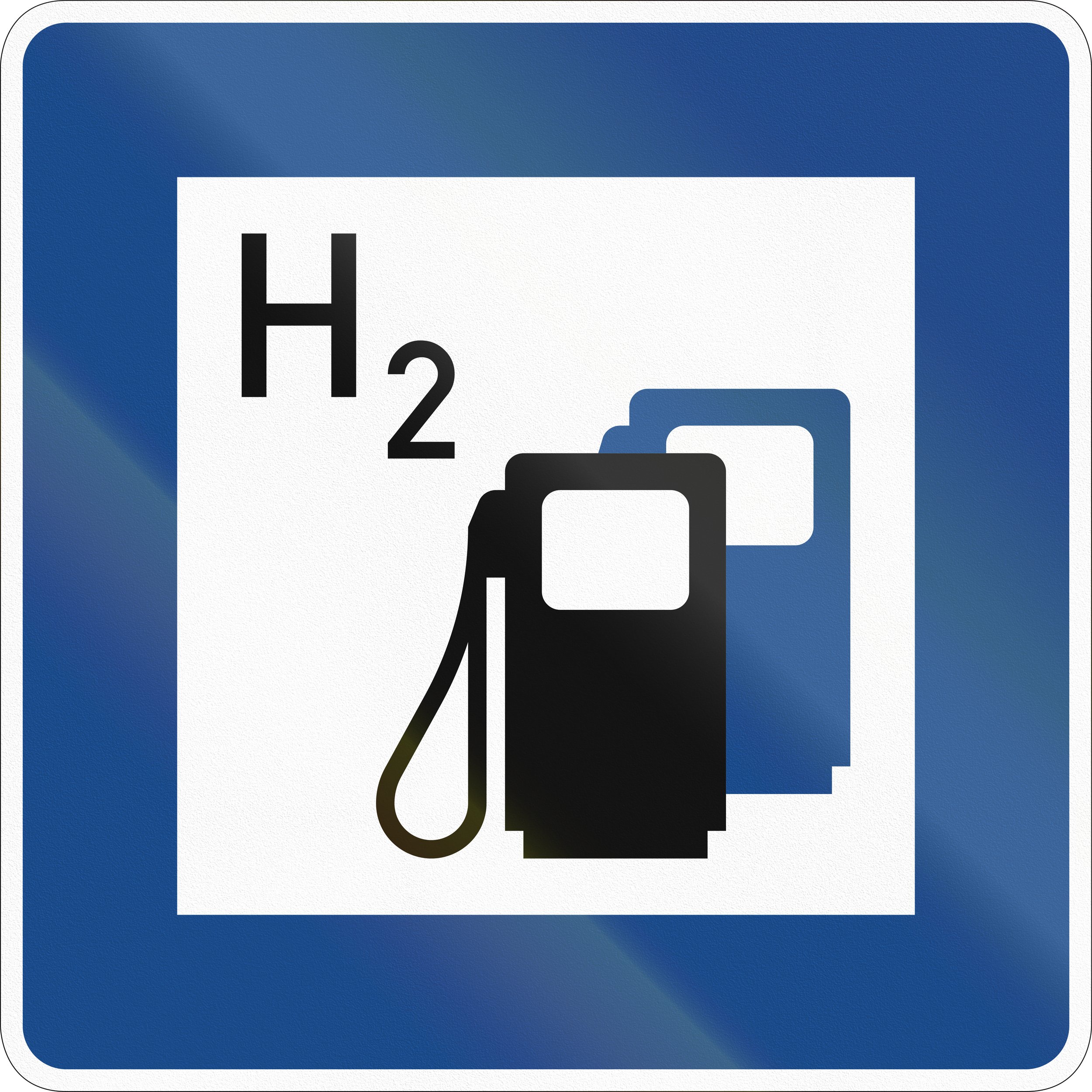

Hydrogen refuel stations

Stocking hydrogen refuel stations via traditional methods of trucking compressed or liquefied hydrogen is not practical. A busy station would require up to forty deliveries a day.

Our technology allows for Solid Hydrogen Cells (SHC) to be delivered via traditional methods, stored on-site indefinitely, and converted into hydrogen when required.

International green hydrogen exports

While specialised hydrogen tankers can carry up to 80 tonnes of hydrogen, we can ship upto 500 tonnes of hydrogen when it is in the SHC form.

What’s more, SHC are stable and safe to transport. We can use the already existing fleet of ships and trucks to transport them.

Mining and metallurgy industries

Mining and metal producing industries are high energy users, with many participants looking to make the shift into renewable space. Our technology can help.

There is a nice synergy between our approach and these industries. We can produce hydrogen from materials these industries already generate, making our technology an attractive proposition.

Where we’re up to and where we’re going

Work done to date

We have successfully tested our approach for green hydrogen production in lab setting.

Our results show we can convert approximately 12% of SHC into pure hydrogen (by mass)

Next steps

Partnering with an academic institution to continue R&D. Focus will be on refining the SHC composition.

Consult industry on application of proposed technology.

Development of commercial application/prototype.